To provide the highest quality products that surpass our customers expectations for safety and reliability. To be a trusted and valued supplier of hydraulic decoking equipment

Trident Process Technologies Inc. was established in 2019 to address the refining industry need for advanced, reliable , functional and proven decoking technologies.

Trident Process Technologies through its exclusive relationship with Jianguang Shanghai Special Equipment Co. Ltd “LJ” will now be offering their exceptional portfolio of engineered process equipment.

LJ has been an industry leader for over 20 years and is the most trusted supplier of automated decoking solutions in Asia. LJ is holder of multiple patents and was one of the first to introduce the streamlined combination drilling & cutting tool design to the market.

These proven technologies are currently used in more than 100 petrochemical facilities and include:

Hydraulic Decoking Equipment

Remote Intelligent Decoking Control Systems

Environmental Coke Handling Solutions

Delayed Coker unit current designs are based on several decades of continual improvements. As refiners push the units to their limits by maximizing throughput and reducing drum cycles having well designed reliable equipment is key to supporting this objective. But the most important mission of both the refiner and the manufacturer of equipment is improving safety.

Operators are removed from cutting deck on modern DCU’s. Operators are no longer are exposed to the hazards of H2S , Steam and high pressure water. Auto switch cutting tools, like the Sure-switch uses water pressure to reliably shift from boring or drilling to cutting.

When used in combination with a powerful software package that has video, acoustic and vibration monitoring like the RIDS (Remote Intelligent Decoking Control System) coker drum drilling cutting can effectively be handled from safe secure remote location with a touch of a button.

EASE OF SERVICING

MAINTENANCE

RELIABLE

SAFE

ADAPTIBLE

COST EFFECTIVE

CUSTOMER SERVICE

We work closely and listen to our business partners in order to establish sustainable business relationships and achieve mutual gains.

To maintain the performance of your investment , we provide ongoing support after delivery to ensure it operates reliably in your system. Spare parts and Service are accessible 24-7

SAFETY

Workplace and product safety are the most important goals at Trident. The safety of our employees is apparent in our values and manifests in the culture of our entire company. We don’t follow industry trends and best practices – we improve them. Safety is at the core of every decision or design improvement we make.

Our team strives to minimize the impact of our operations on the environment and follows LJ’s commitment to be ISO 14001 compliant.

QUALITY ASSURANCE

Strict quality standards,test procedures guarantee that you receive the very highest quality without exception. Assembled in the USA , patented and meet applicable ASME standards.

We have over 20 years of experience and have installed over 100 systems.

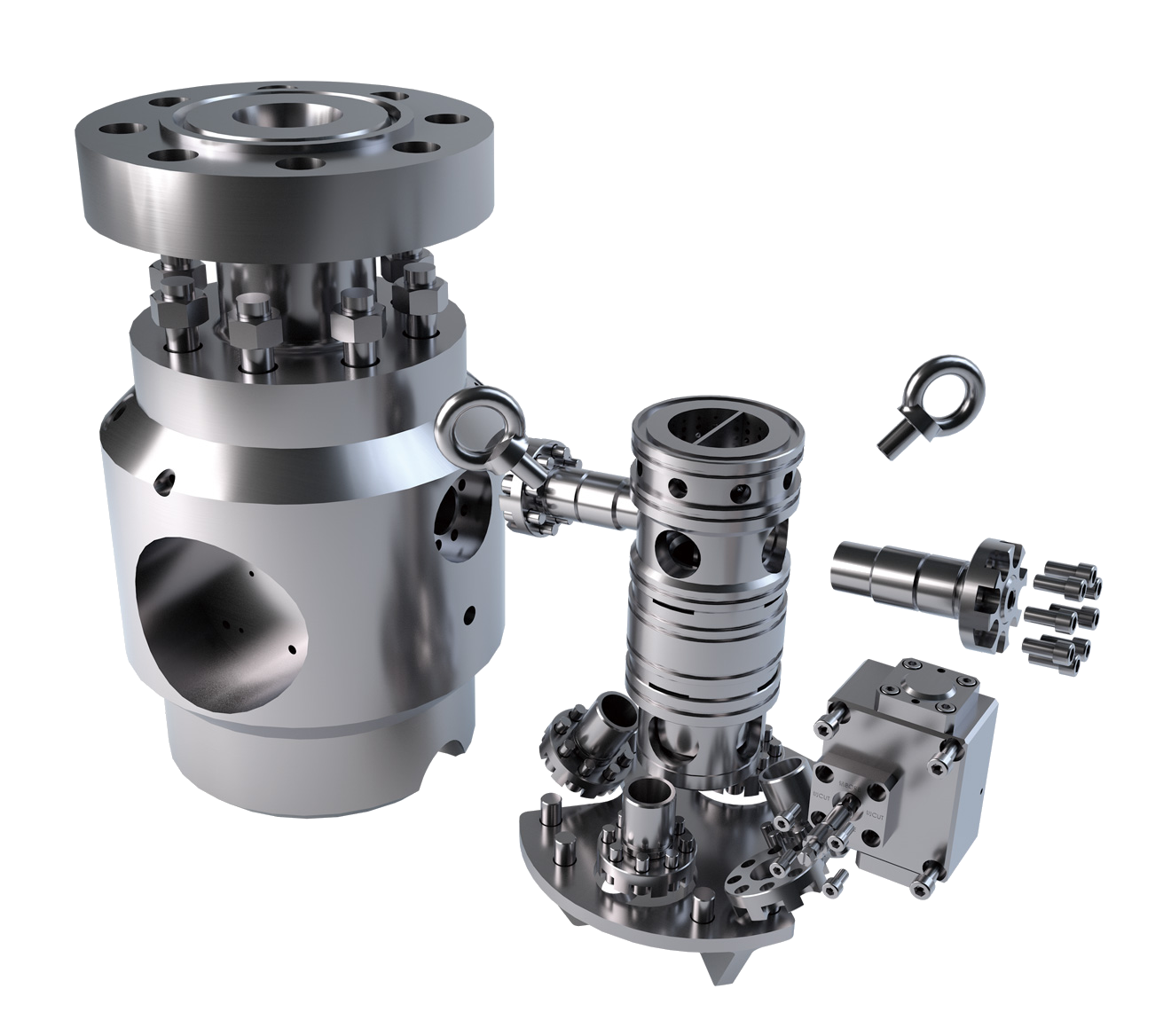

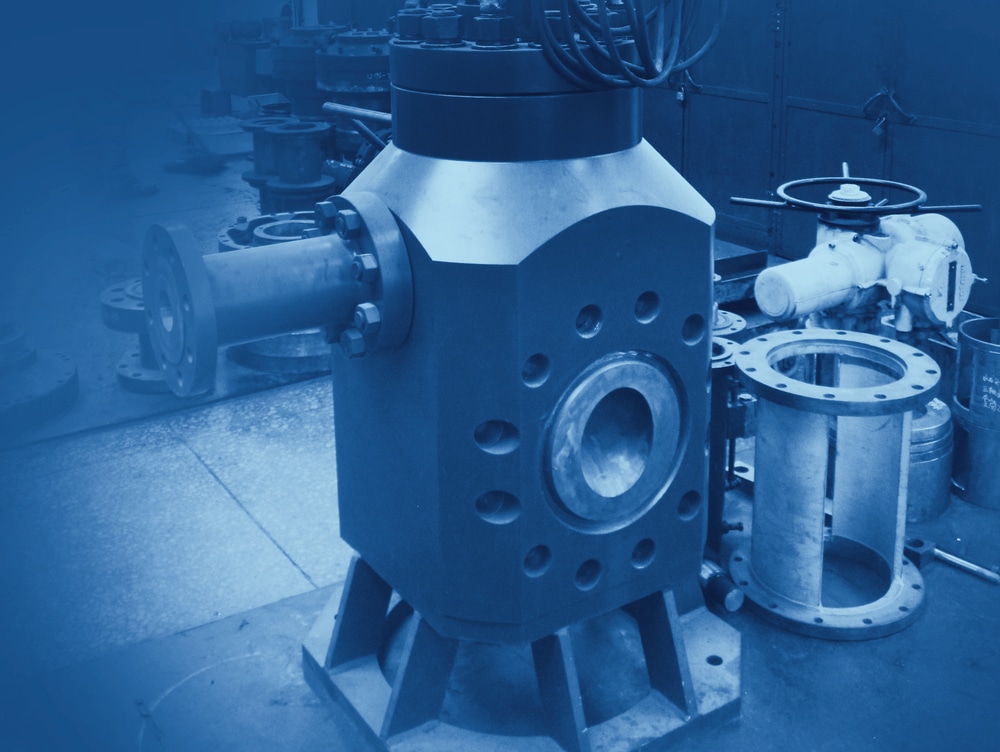

Control Valve

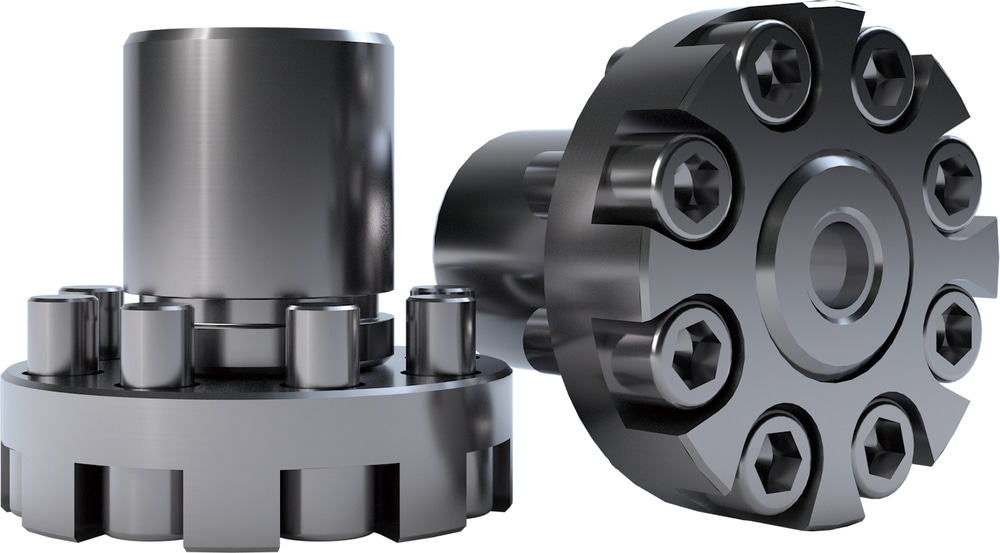

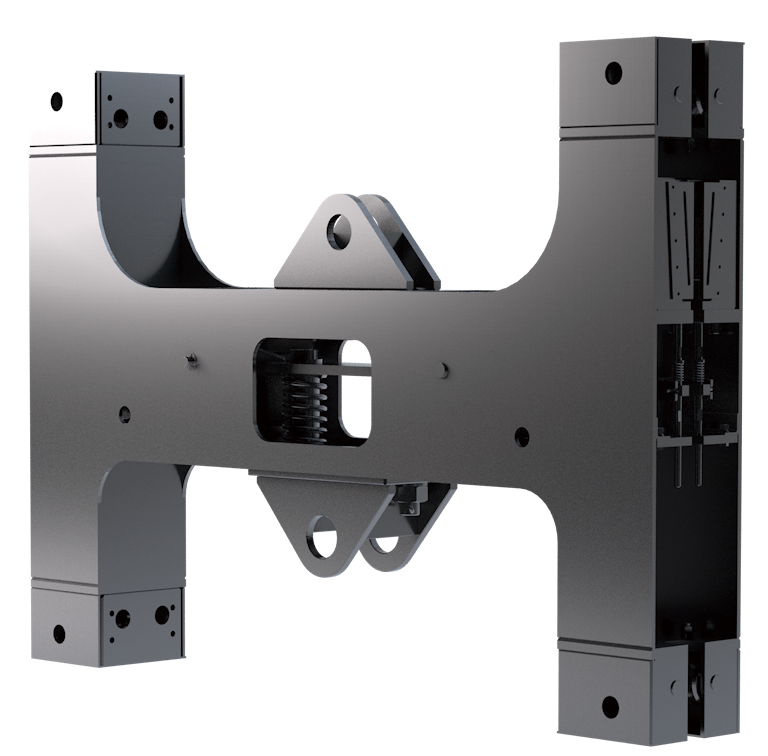

Cutting tool

Cutting tool

Cutting tool

Cutting tool

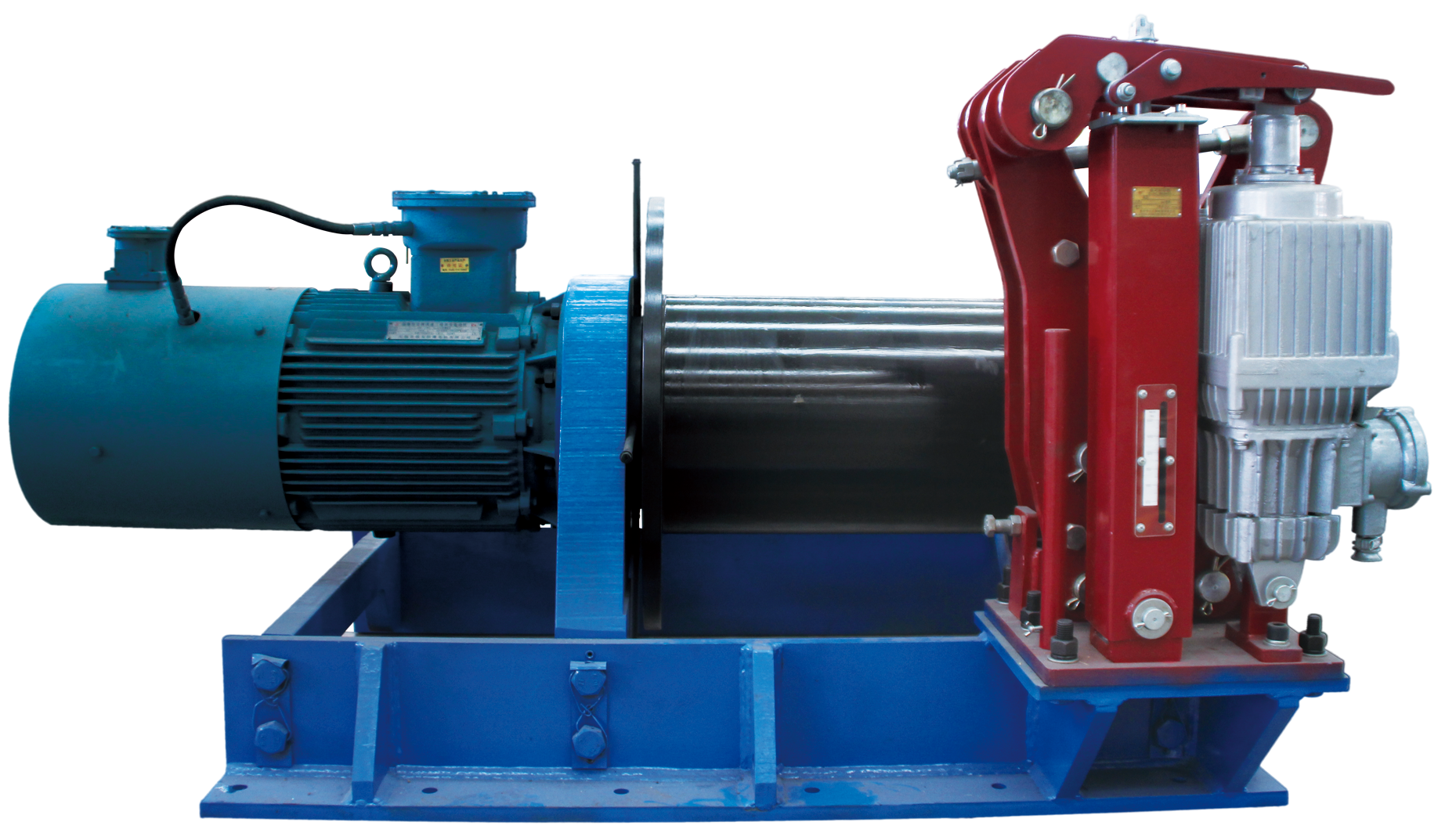

Fall arrest Winch

Fall arrest Winch

Contact Trident Process Technologies Inc.

We’re Here To Help

Monday-Friday: 9:00 – 18:00

Saturday: 11:00 – 17:00

Sunday: 11:00 – 17:00

Phone: +1 888-555-5555

Mobile: +1 888-555-1234

Fax: +1 888-555-5532