Overview

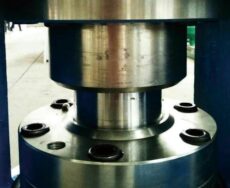

Our patented top drive unit consists of a gooseneck connector, wash pipe assembly, output shaft and drive unit. The unit’s primary function is to rotate the drill stem and transfer cutting fluid through the stem to the combination cutting tool. Its lightweight but heavy-duty design is engineered to withstand the axial and suspended loads of the drill stem and cutting/boring tool. When paired with our Sure Switch combination tool the risk of cave ins or stuck drill stems are reduced.

Adaptable Connections and Drive Units

ANSI class 2500lb flanges are standard, or we can adapt with other sizes to match your system. The drive unit options include pneumatic, hydraulic with control unit or electric with variable frequency drives. Units are fully rated for hazardous areas and provide efficient high torque variable drill stem speeds.

Ease of Maintenance and Improved Safety

Rotary dynamic seal cartridges are designed to be replaced as a fully assembled part. It is quickly and easily swapped in the field having to disassemble other components.

Extended Service Life

Rotary Improved multi stage seal packing on our rotary dynamic cartridges provides safe reliable sealing performance. Fully enclosed multi-stage straight/helical gear transmission design with long life bearings provides safe reliable operation with minimal preventative maintenance.